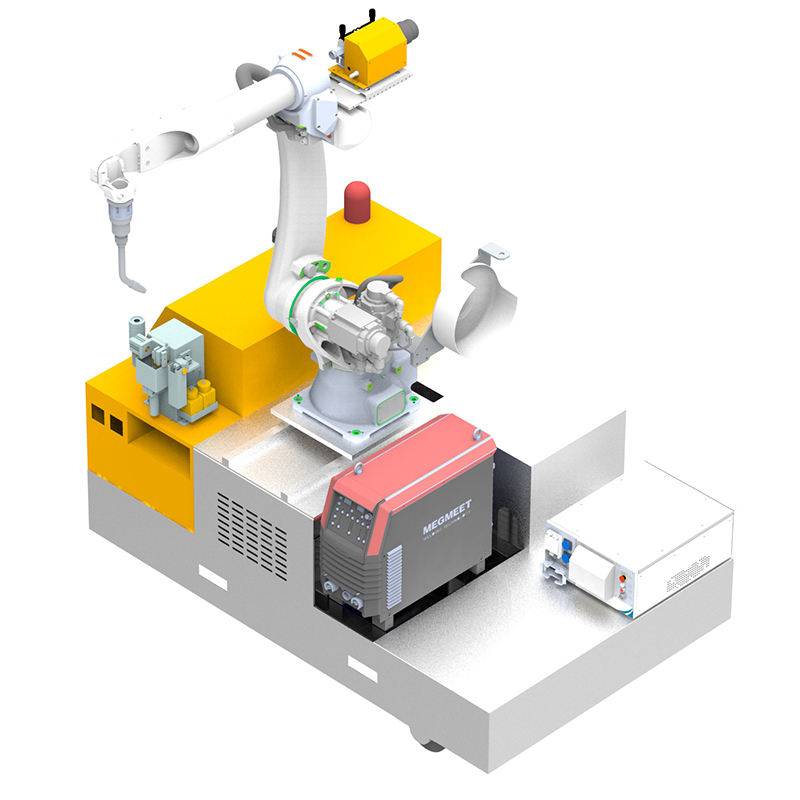

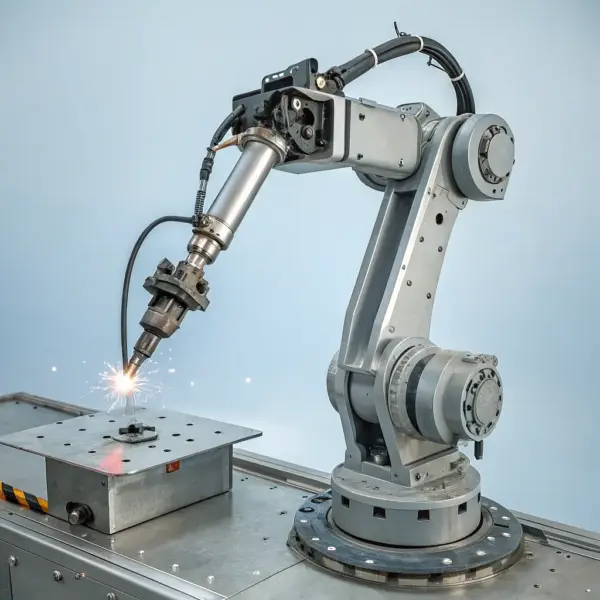

Introducing our Tracked Wheeled AGV Welding Robot, a cutting-edge solution designed for precision and efficiency in automated welding applications. Engineered with advanced tracking technology and robust wheeled mobility, this robot seamlessly navigates complex environments, ensuring consistent performance and high-quality welds. Ideal for industrial settings, it enhances productivity while reducing labor costs, making it an essential asset for modern manufacturing operations.

Products Description

Performance characteristics Structure: Tracked AGV carts usually use chains or tracks as transmission devices, while wheeled AGV carts use wheels as moving parts. Applicable environment: Tracked AGV carts are suitable for various ground conditions, including uneven ground, muddy ground, etc. They can work in harsh environments such as factory workshops, warehouses, etc. Wheeled AGV carts are more suitable for driving on flat ground, such as offices, hospitals, etc.O Flexibility: Tracked AGVs have less flexibility and a larger turning radius, making them unsuitable for working in narrow spaces. Wheeled AGVs are more flexible and can move freely in narrow passages and spaces. Speed and efficiency: Generally speaking, wheeled AGVs are faster and more efficient. Tracked AGVs speed are slower but can carry heavier cargo. Tracked Wheeled AGV Welding-Robot Carts Welding Workstation Welding Robot For Sale

Parameter

| Total power | 50KVA |

| Working power supply | 3X380V 50Hz 3-phase 5-wire system 3P,380V,50Hz |

| Working power supply mode | Coll cable power supply |

| Machine weight | 2500Kg |

| Dimension | 3000mmX1500mmX2400mm |

| Robot model | CRP2010A |

| Welding power source | NBC500RP Plus Aotal NBC500RP Plus |

| Visual point cloud accuracy | 0.1mm |

| Vision software | TracerStudio |

| Moving drive | Steering wheel type |

| Operation type | Remote control |

| Moving speed | 2.2km/h |

| Environment temperature | 0℃-+45℃ |

| Relative humidity | ≤90%RH(non-condensing) |

Related products

-

Sale

Gantry welding robot solution

$50,000.00Original price was: $50,000.00.$40,000.00Current price is: $40,000.00. -

SteelForgeTech PrecisionWeld 500

$125,000.00 -

Sale

SteelForgeTech CompactWeld 150

$75,000.00Original price was: $75,000.00.$56,250.00Current price is: $56,250.00. -

Sale

SteelForgeTech MegaWeld X

$350,000.00Original price was: $350,000.00.$262,500.00Current price is: $262,500.00. -

Sale

SteelForgeTech RoboWeld 3000

$150,000.00Original price was: $150,000.00.$112,500.00Current price is: $112,500.00.

Watch Related Videos

Loading specialized videos...